- Metric Thread

- Metric Thread - Bolt Torque table

- Metric Thread - Pitch

- Metric Thread - Tap Drill table

- Metric Thread - Clearance Hole table

- Metric Fine Thread - Bolt Torque table

- Metric Fine Thread - Pitch

- Metric Fine Thread - Tap Drill table

- Metric Wrench Sizes

- Sheet Metal Screws Pilot Hole Sizes

- Cable Gland Sizes

- Trapezoidal Thread Sizes

- Cutting Metric Thread

- Inch Thread

- The Screw

- Drill correctly

- Which Dowel

- Materials

- Language

Metric clearance Hole

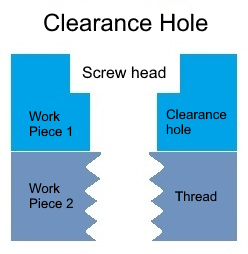

A through hole or clearance hole for a screw is a common design in fastening technology. It allows the screw to pass through the workpiece to make a connection on

the opposite side. The through hole has a specific size that aims to adequately accommodate the screw and ensure a stable connection.

There are three common ways to make a through hole for a screw. These options are based on different tolerance grades and determine the exact size of the hole:

Fine: The through hole with a fine tolerance grade provides a precise fit to ensure an optimal connection with the screw. It ensures high accuracy

and a tight fit between the screw and the workpiece.

Medium: The through hole with a medium tolerance class provides some clearance and allows more flexible positioning of the screw. It is suitable for applications where a slightly

larger tolerance is acceptable or when a precise fit is not essential.

Coarse: The through hole with a coarse tolerance grade provides the greatest clearance and allows a looser fit. It can be useful when a loose fit is sufficient or when some room

for movement is desired.

Please note that exact diameters and tolerances may vary depending on requirements, standards and specific applications. It is important to consult the exact specifications and requirements of appropriate standards or engineering drawings to determine the correct size of through hole for the appropriate screw.

The picture on the left shows a through hole for a cylinder head screw. In order to connect workpiece 1 with workpiece 2, a through hole is drilled in workpiece 1. The correct diameter can be found in the following through-hole table.

Clearance Hole Chart for metric sizes (Through Hole Chart)

| Metric thread sizes |

Fine (mm) |

Medium (mm) |

Coarse (mm) |

| M1 | 1,1 | 1,2 | 1,3 |

| M1,2 | 1,3 | 1,4 | 1,5 |

| M1,4 | 1,5 | 1,6 | 1,8 |

| M1,6 | 1,7 | 1,8 | 2 |

| M1,8 | 2 | 2,1 | 2,2 |

| M2 | 2,2 | 2,4 | 2,6 |

| M2,5 | 2,7 | 2,9 | 3,1 |

| M3 | 3,2 | 3,4 | 3,6 |

| M3,5 | 3,7 | 3,9 | 4,2 |

| M4 | 4,3 | 4,5 | 4,8 |

| M5 | 5,3 | 5,5 | 5,8 |

| M6 | 6,4 | 6,6 | 7 |

| M8 | 8,4 | 9 | 10 |

| M10 | 10,5 | 11 | 12 |

| M12 | 13 | 13,5 | 14,5 |

| M14 | 15 | 15,5 | 16,5 |

| M16 | 17 | 17,5 | 18,5 |

| M18 | 19 | 20 | 21 |

| M20 | 21 | 22 | 24 |

| M22 | 23 | 24 | 26 |

| M24 | 25 | 26 | 28 |

| M27 | 28 | 30 | 32 |

| M30 | 31 | 33 | 35 |

| M36 | 37 | 39 | 42 |

| M42 | 43 | 45 | 48 |

| M48 | 50 | 52 | 56 |

| M56 | 58 | 62 | 66 |

| M64 | 66 | 70 | 74 |

* All information without guarantee.

The following topics may also be of interest to you: